Customizing the Design

The kayak design can be customized in a number of ways to fine-tune

it to the paddler's preferences. These adjustments are optional.

The design as provided is applicable to a wide range of paddlers.

However, if you're a person who likes to tinker, these settings

are available to the builder who wants to make the final tweaks

to the design.

The following adjustments can be made prior to printing the forms:

- The size and shape of the cockpit

- The target displacement based on the weight of the kayak, cargo,

and paddler

- The design waterline (DWL) height to equalize design/target displacements

- The location of the paddler's center of gravity (CG)

The Customization Process

If you're unfamiliar with the KayakFoundry software, here's an

description of how to customize the design. The order of customization

listed is more fine-grained the further you go down the list. The

first adjustment is the cockpit size, and you may choose to make

that change and stop there. Or, you can continue down the list to

make additional changes. The choice is up to you.

| Install the KayakFoundry

software on your computer. The software is distributed in

a zip file, and installation is as simple as unzipping the file

to a location on your hard disk. |

|

| Run kfoundry.exe,

select File|Open

and choose the design .yak

file. The design will open and will be displayed in a number

of views. |

|

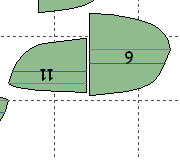

| The top panel is the Plan view and shows the kayak

from a birdseye view. Click in this panel, and three control

points will be displayed in green. The one on the centerline

allows you to adjust the length of the cockpit. The remaining

two allow you to adjust the curvature and width of the cockpit.

Click and drag the control points to move them. |

|

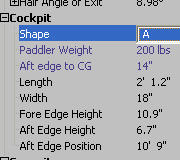

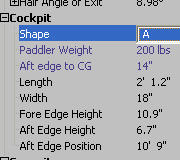

| Alternatively, there are 3 predefined shapes

that can be changed in the Hydrostatic panel. Double-click on

the Cockpit Shape entry, and select from A, B, or C. |

|

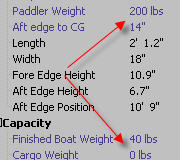

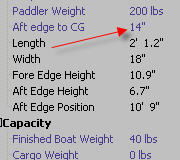

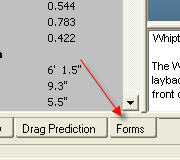

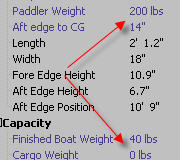

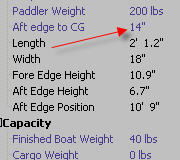

| In the Hydrostatic panel, you can alter the estimated

paddler weight, cargo weight, and kayak weight. Double-click

on each entry to edit the value. A reasonable kayak weight is

40-45 lbs for this kayak. Change the paddler and cargo weight

values to reflect the most common expected load for the kayak.

These individual weights combine to form the target displacement. |

|

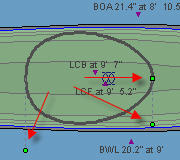

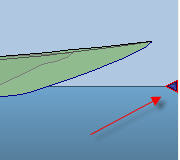

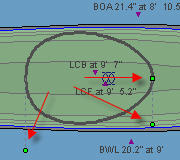

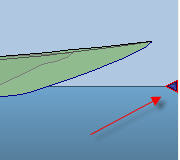

| Click in the Profile panel, and then click on

the triangular control on the far right on the waterline. The

control will be highlighted in red. When selected, the up/down

arrows make fine adjustments to the design waterline (DWL).

Move the DWL up or down until the design displacement (the displacement

of the underwater portion of the hull) is approximately equal

to the target displacement (the combined weight of kayak, paddler

and cargo). This adjustment causes the kayak's center of buoyancy

(CB) to be re-computed then and the center of gravity (CG) shifted

to be directly over the CB. In other words, the program shifts

the cockpit so that the overall CG remains directly over the

CB. This ensures that the kayak will maintain the designed trim

when loaded to the target displacement. |

|

| In the Hydrostatic panel, you can alter the distance

of the paddler's CG to the aft edge of the cockpit. The default

value of 14" is a good estimate for most paddlers. If you

want to find your own CG, sit on the floor with your legs straight

out in front of you. Push down on the floor with your hands

on either side of your legs until you find the point lift yourself

off the floor (legs still straight out) and your body is balanced.

Measure the horizontal distance from your hands on the small

of your back. Alternatively (and easier if you've got the ingredients),

set a 2x6 plank over a dowel (or broomstick) like a teeter-totter,

sit on the plank and position yourself to where you're balanced,

then measure the distance from the dowel to the small of your

back. Either way you arrive at the distance, add to this value

any space you'd like between your back and the aft edge of the

cockpit (typically, I add 4", but that's just my preference).

Enter the total into the cockpit setting for "Aft edge

to CG". |

|

Forms Setup

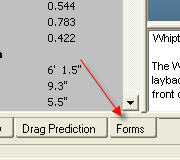

| Once you've completed any customizations to the

design (if any), you're almost ready to print the forms. At

the bottom of the main program window, select the tab marked

"Forms". This window will show you how the forms will

be printed relative to each other. The grid provides a rough

indication of how the forms will print on 8-1/2" x 11"

sheets of paper. KayakFoundry will print on any size of paper

that you choose, so just use the grid as a guideline. Before

printing, there are a couple options to consider. |

|

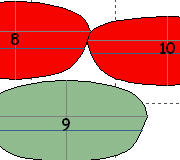

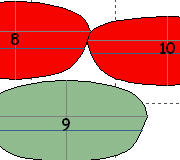

| If any of the forms are shown in red, this indicates

an overlap, and in general, it's best to print without overlap.

Click and drag the forms to arrange them on the canvas until

there are no overlaps. |

|

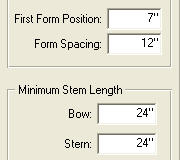

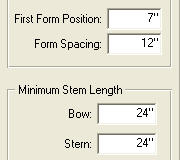

| You can also change the form spacing and starting

form position if you like, but this should not be necessary.

The forms are already setup for 12" spacing, which is typical.

Also, the length of the stem forms can be adjusted, but the

minimum of 2 ft is generally long enough. |

|

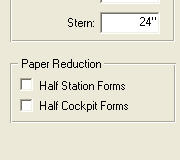

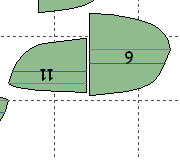

| If you want to conserve paper, you can consider

printing half-forms. This requires you to trace the form outline

(and significant reference lines) on to your form material (e.g.,

plywood), flip the paper over the centerline and trace the other

half. It's a little tedious, but if you want to conserve paper,

its an option. After selecting one or both of the half-form

checkboxes, you'll need to reposition the forms to place them

as close as possible. |

|

| A word about positioning forms: While holding

the left click on a form, you can use the left/right arrow keys

to rotate the form. Simultaneously holding the shift key makes

the rotation snap to 45-degree increments. If you're printing

half-forms, you can rotate every other form 180 degrees so you

can place 2 forms centerlines close to each other. |

|

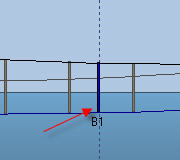

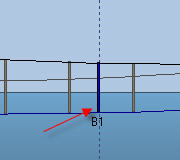

| There are two bulkhead forms pre-defined and

are named B1 and B2. If you intend to install bulkheads, you

may need to reposition them depending on the cockpit movement

due to customizations. The bulkheads on the profile view can

be click-dragged to position. If you don't need bulkheads, you

can just drag them off the end of the design to remove them.

Even if you do build the bulkheads, you can print those forms

later (generally the bulkheads are installed near the end of

the project). |

|

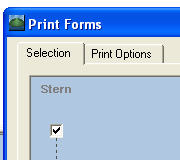

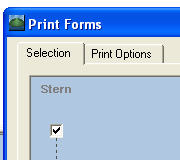

| Select File|Print

Forms to open the Print Forms dialog. There are two tabs on this

dialog - Selection and Print Options. The Selection tab allows

you to choose which forms you want to print. You can choose to

print 1, some, or all the forms at once. Some people choose to

print one form at a time to make the taping-together process a

little simpler. Each page will have corner registration marks

to help align them properly, but it can be a little unwieldy when

all forms are printed together. It helps to have a large worksurface

if you go this route. Here's the result. |

|

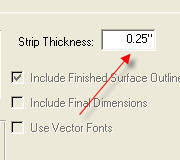

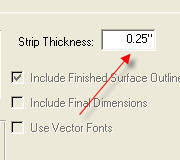

| Before printing, take a look at the Print Options

tab. Most of the options are self-explanatory, but I'll mention

a couple of the significant ones. The Strip Thickness is set to

1/4" by default. Most builders use 1/4" strips, but

if you choose to use thinner strips, specify the actual thickness

here. This will ensure that the form outline is adjusted to account

for the strip thickness. |

|

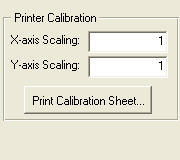

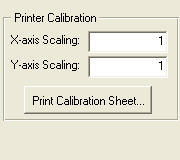

| The Printer Calibration allows you to fine-tune

the scaling in case your printer doesn't print accurately sized

forms. Normally, the default settings work just fine. |

|

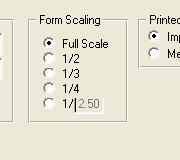

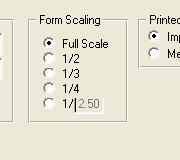

| The Form Scaling lets you print smaller forms if

you want to build a model. |

|

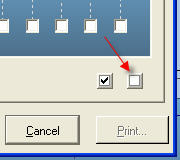

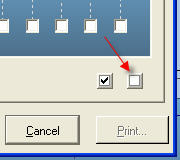

| Click back to the Selection tab, and click the

white square button in the lower left. This clears all the checkboxes.

Even if you plan to print all the forms together, it's always

a good idea to print a single form to evaluate the result. Choose

one of the larger forms near the center of the kayak to ensure

that you print a multiple-sheet form (to get a feel for how the

pages are assembled). Click the checkbox to select the form for

printing. |

|

Now... click Print. This will open the standard Windows

Print Dialog. Select your printer, and then be certain to specify

the correct paper size that you're using. The selected paper size

is reported to KayakFoundry, which allows it to maximize the use of

the printable area on the paper.

Once you are satisfied with the results of printing

one of the forms, you're ready to print the rest. You can choose to

print them all at once, or one at a time (by clearing all checkboxes

but one before clicking on the Print button). Use the registration

marks at the corners of the pages to align the pages properly. The

legend at the top of the page indicates the page and its position

in relation to others in the print sequence.

The forms are printed with outer dashed line that represents

the finished kayak surface, and a bold solid line that is the form

edge. Cut all forms out on the solid line. This can be seen on this

sample form.

Finally, cut out the forms and glue them to your form

material (plywood, particle board, MDF, etc.). I've found that 3M

77 spray adhesive works well for this. Cut out the forms and start

your project!

|